Optimizing Maintenance in the Chemical Sector

Challenges in Chemical Industry Maintenance

Why Task360 is Essential?

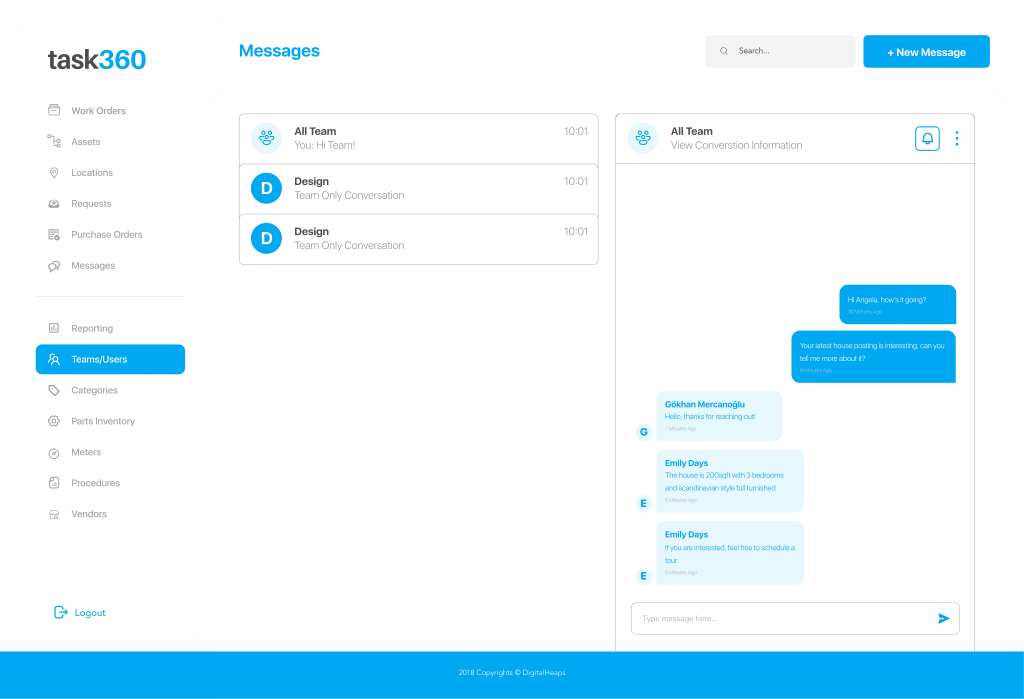

Task360 provides a tailored solution for the chemical industry by integrating asset management, maintenance scheduling, and compliance reporting into one platform.

This comprehensive approach ensures that equipment runs efficiently, maintenance is proactive, and safety and regulatory standards are consistently met.

Imagine a chemical plant where every piece of equipment is continuously monitored and maintained, ensuring uninterrupted production and compliance with all safety regulations.

Don’t let outdated maintenance practices hinder your operations.

Key Features of Task360

Comprehensive Asset Management

Advanced Maintenance Scheduling

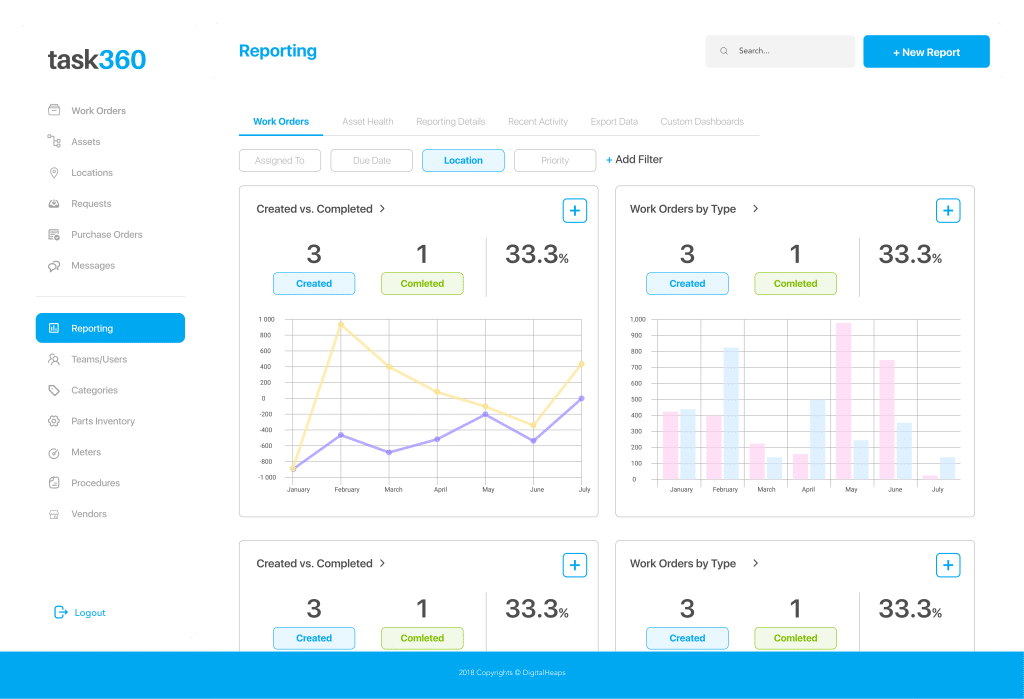

Robust Maintenance Reporting

Let’s start optimizing your maintenance processes and achieving outstanding results together!

What our clients are saying about us

Ernest Smith

Implementing Task360 has completely transformed our approach to maintenance management. We’ve experienced a 24% decrease in downtime and an impressive 11% increase in asset longevity. The system's seamless integration has not only streamlined our workflows but also significantly reduced operational costs.

Stella Smith

"Task360 has been a game-changer for our maintenance strategy. We achieved a 26% reduction in equipment downtime and extended asset lifespans by 11%. The system’s efficiency and ROI of 652% have exceeded our expectations, greatly enhancing our operational performance."

Vincent Smith

"Adopting Task360 has revolutionized our maintenance operations. We've achieved a remarkable 23% reduction in equipment downtime and extended asset lifespans by 12%. The intuitive integration of the system has optimized our maintenance workflows and provided substantial cost savings."

"With Task360, we completely revamped our maintenance processes. The system helped us reduce equipment downtime by 25% and extend asset lifespan by 10%. The return on investment has been phenomenal, and our operations have never been more efficient."